Design

As the building/slab-to-slab height increases, the wind load on the facade increases. The wind speed varies from place to place/city to city. Some regions experience hailstorms and lashing rains whereas some regions are hot and arid. The glass panel/window should be able to withstand all these external environmental factors & perform smoothly day after day, year after year. Superior design of profiles by weight optimization, world-class accessories and expert fabrication on imported machines ensure structurally stable and aesthetically pleasing systems. The profiles are selected in accordance to IS 875 Part III, and also conform to various European and BS standards.

Specialized Know - How?

We have in house facility for designing, engineering, structural and wind load Calculations, Shop drawings etc. System design involves external factors like wind loads, internal processes like extrusion design / accessory design, surface treatment, fabrication, installation, cur rent t rends in bui lding technology, glass facade, seismic proofing of building, noise reduction, thermal insulation and many more other factors. With KH you will experience the difference from initial design stage to final product supply and installation.

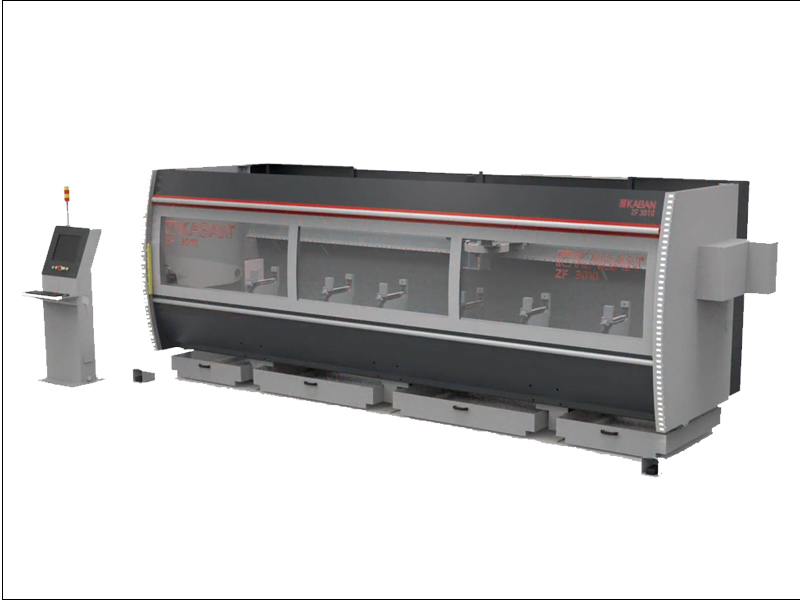

Machinery

Machines form a very important part of the system. Their usage ensures smooth finishes, hairline/burr free joints, faster productivity, dimensional accuracy and repeatability. State-of-Art Machinery from MUART (Turkey)

Profiles

The extrusions/profiles are produced from virgin metal, Aluminium alloy is 6063, tempered at T6, conform to various European and BS standards and uPVC profiles of German quality.

Accessories

It forms the heart of the system. The profiles and accessories are designed to fit each other. The accessories are designed to suit the system. These accessories ensure smooth, trouble free operation and prevent creaking, jamming and air/water leakage.